Research

We are conducting both basic & applied research on materials nanotechnology focusing on self-organization process.

Dynamics of nano-particle during dehydration andenvision of flow by SNAP

Dynamics of nano-particle during dehydration andenvision of flow by SNAP

We are developing a simulation infrastructure of dispersion/aggregation of colloids under flow/drying environment, which are important in various applications such as inks, cosmetics, foods, medicals. When we understand the mechanism common for substances, we can conduct simulations commonly. Such simulations enable analysis at time & spatial scales which is difficult by experiments. In addition, safety & risk of nanomaterials is also important. We are developing an infrastructure systematically evaluating nanomaterials properties as well as their fabrication processes.

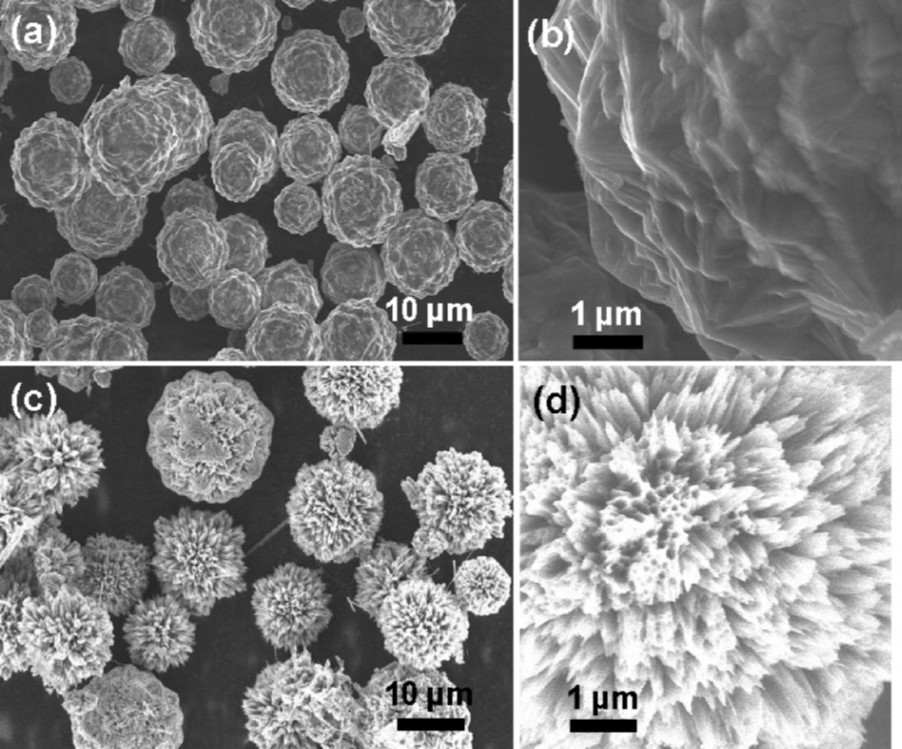

spherical Si particle(top) and burr-like Si particle N. Uesawa et al., Chem. Eng. J. (2011)

spherical Si particle(top) and burr-like Si particle N. Uesawa et al., Chem. Eng. J. (2011)

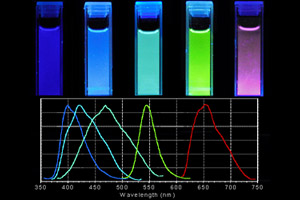

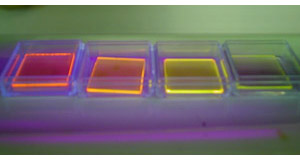

Full-Color PL of Si-QDs by PE-CVD

Full-Color PL of Si-QDs by PE-CVD

Single-crystalline silicon realized semiconductor industry, and it is leading solar cells at the same time. Ordinary Si-crystal generation method requires too much cost and can generate too small crystals for solar cell fabrication. We are developing single-crystalline balls or thin films to improve the efficiency of silicon usage by several-ten times. We are also developing a new chemical route for feedstock production of high purity silicon. Silicon changes its band structure when their size decreases to nanometer-scale. We are trying to apply silicon nanoparticles to bio-markers for medical diagnostics.

different color luminescence

different color luminescence

by controling structures of conductive polymer

Organic thin film semiconductor is a key to realize environmentally friendly society. We study relationships between film structure and device quality under wet process which is good for mass production and require less cost than ordinary ones. We are also studying crystal growth processes of organic semiconducting thin films for thin-film transistors & luminescence devices.

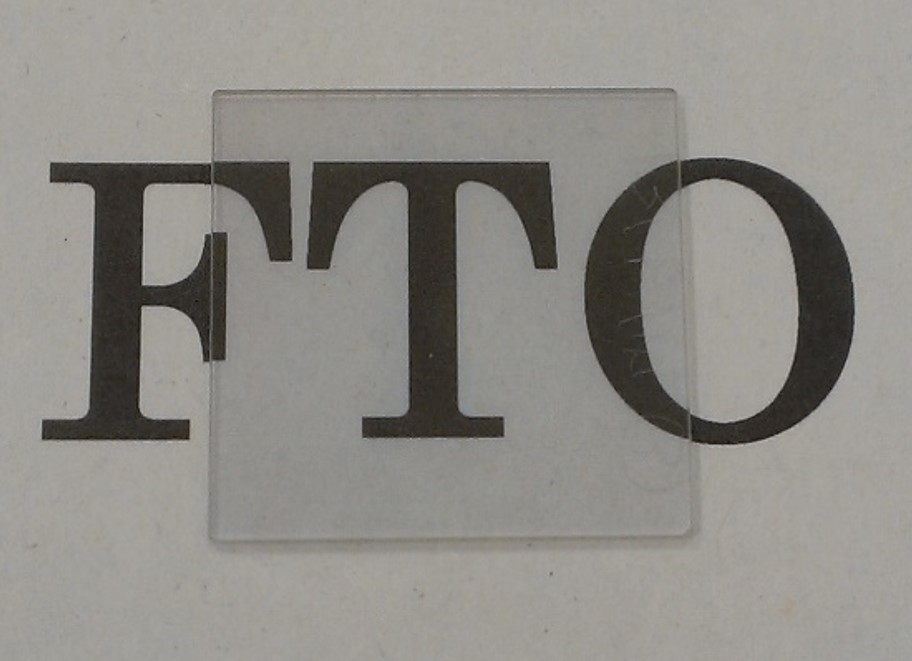

transparent conductive film

transparent conductive film

Oxcide semiconductors such as stannous oxide, zinc oxcide and amorphous IGZO are gathering many attention and regarded as next generation electronics due to transparence and high career mobility, so feasible low price process is now required. We use spray deposition for merits of mass production and low tempreture, and aim to apply for display, solar pannel, Thermo-electric devices and so on.